Garis Besar Isi Buku

STUDI TENTANG KONDISI PASAR DAN PROSPEK INDUSTRI BAJA DI INDONESIA, 2015

Outline of Book Contents

STUDY ON THE MARKET CONDITIONS AND PROSPECTS OF STEEL INDUSTRY IN INDONESIA, 2015

AVAILABLE IN INDONESIAN & ENGLISH VERSIONS

INDONESIAN VERSION

Pelanggan yang kami cintai! Salam sejahtera.

Semoga kita semua ada dalam lindungan Tuhan!

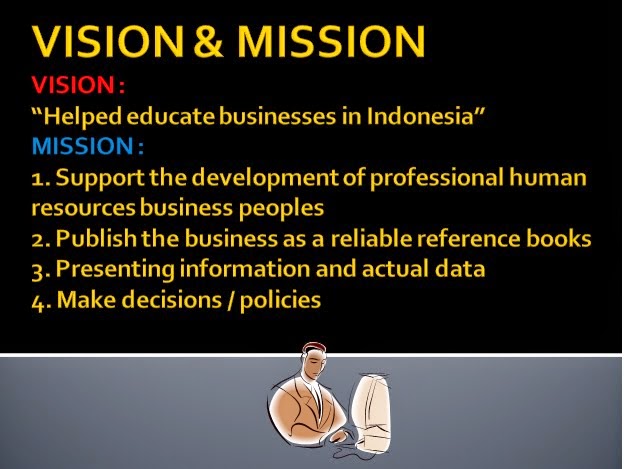

Latar Belakang Commercial Global Data Research (CDR)

Pelanggan yang kami cintai! Salam sejahtera.

Semoga kita semua ada dalam lindungan Tuhan!

Kami adalah sebuah lembaga Konsultan, Survey, Riset dan Pelaporan di bidang data riset secara global, menyajikan berbagai informasi bisnis aktual yang meliputi sektor Industri manufaktur, pertambangan, perbankan, asuransi, studi kelayakan, dan jasa riset lainnya.

Kami hadir sebagai mitra konsultan Anda, untuk memberikan informasi aktual yang Anda perlukan guna menentukan arah kebijakan dalam mengembangkan perusahaan Anda. Salah satu produk buku studi yang kami tawarkan kepada Anda adalah “BUKU STUDI TENTANG KONDISI PASAR DAN PROSPEK INDUSTRI BAJA DI INDONESIA 2015”.

Kami tawarkan Buku tersebut kepada Anda seharga Rp.7.000.000 (Tujuh juta rupiah), guna membantu para pelaku bisnis pada Industri Baja, membantu para Investor, membantu pihak Perbankan atau Kreditor, dan pihak lainnya yang terkait, dengan cara melihat peta kekuatan diantara para pesaing/partner Anda, baik pesaing dari luar negeri maupun dalam negeri, mempelajari perkembangan Ekspor dan Impor produk Baja di Indonesia, mengetahui hambatan dan peluang bagi perusahaan yang kondisinya berfluktuasi, mengetahui Main Market dari setiap perusahaan Baja, mengetahui pangsa pasar luar negeri, serta informasi lainnya yang perlu Anda ketahui.

Seberapa besar kontribusi perusahaan Anda dalam meningkatkan kapasitas produksi guna memenuhi pesanan dari para buyer baik lokal maupun internasional, mencermati setiap peluang yang ada, dan diharapkan dengan memiliki buku ini, perusahaan Anda menjadi lebih produktif, efisien, lebih maju dan bersaing secara sehat.

KATA PENGANTAR

Industri baja merupakan salah satu industri strategis di Indonesia. Sektor ini memainkan peran utama dalam memasok bahan-bahan baku vital untuk pembangunan di berbagai bidang, mulai dari penyedian infrastruktur (gedung, jalan, jembatan, jaringan listrik dan telekomunikasi), produksi barang modal (mesin pabrik dan material pendukung serta suku cadangnya), alat transportasi (kapal laut, kereta api dan relnya, otomotif), hingga persenjataan. Atas perannya yang sangat penting tersebut, keberadaan industri baja menjadi sangat strategis untuk kemakmuran suatu negara. Indonesia memiliki potensi yang besar untuk mengembangkan industri baja. Pengembangan tersebut berupa pengembangan ke arah investasi. Oleh karena itu pengembangan investasi yang dapat dilakukan pada industri baja yang ditinjau melalui analisis pasar yang telah dilakukan, diketahui masih belum terpenuhinya kebutuhan baja dalam negeri.

Perlunya usulan pengembangan industri baja pada daerah-daerah yang memiliki potensi untuk pengembangan industri baja. Selain itu, pengembangan pada sektor industri hulu perlu dilakukan. Tujuan dari studi ini adalah untuk meningkatkan pengembangan industri baja yang berperan strategis bagi bangsa, namun belum dilakukan secara optimum untuk menjadi industri yang tangguh dalam negara ini.

Perkembangan global konsumsi baja yang semakin meningkat telah memicu industri baja untuk meningkatkan kapasitas produksinya. Akibatnya produksi bijih besi juga mengalami peningkatan yang signifikan. Hal ini diperkirakan suatu saat akan menimbulkan kelangkaan dan krisisnya bahan baku untuk industri baja ini.

Hasil evaluasi, kebutuhan bijih besi untuk industri baja PT. Krakatau Steel untuk beroperasi selama 20 tahun akan mengalami defisit sebanyak 283.980.127 ton. Dengan demikian cukup beralasan bijih besi menjadi komoditas mineral strategis nasional yang dikelola oleh negara.

Untuk itu dalam jangka panjangnya diperlukan kebijakan pemerintah yang mendukung kepentingan strategis nasional ini.

Kebutuhan baja tahun 2015

Kebutuhan logam besi baja di dalam negeri pada tahun 2015 diperkirakan mencapai 13 juta ton. Sementara pemenuhan permintaan tahun 2014 lalu dari industri domestik belum 100%.

Menurut Direktur Industri Material Logam Dasar Ditjen Basis Industri Manufaktur Kementerian Perindustrian (Kemenperin), Budi Irmawan, bahwa trend permintaan logam besi baja terus meningkat.

Pada 2015 kebutuhannya sangat dipengaruhi kebijakan kabinet baru terhadap akselerasi proyek infrastruktur. Pada tahun 2014 lalu, kebutuhan logam besi baja di tanah air sebanyak 12 juta ton. Prognosis permintaan sejumlah 13 juta ton pada tahun 2015 menunjukkan adanya pertumbuhan sekitar 8,3% terhadap target tahun 2014.

Belum semua kebutuhan dipenuhi dari produksi dalam negeri, terdapat impor sekitar 40% dari kebutuhan. Kapasitas produksi terpasang untuk crude steel domestik berkisar 4 juta ton. Ketika sudah diolah menjadi produk, maka jumlahnya menjadi 8 juta ton. Utilisasi pabrik agak rendah yaitu sebesar 60% sampai 70% karena ada beberapa spesifikasi yang belum bisa dibuat di dalam negeri.

Sepanjang semester pertama tahun 2014, industri logam dasar besi dan baja tumbuh 1,42%. Persentase ini menyusut drastis terhadap pertumbuhan pada semester pertama tahun lalu mencapai 12,47%. Kondisi ini terpengaruh depresiasi rupiah, kenaikan upah pekerja, lonjakan tarif listrik, dan pemilihan presiden.

Berdasarkan data dari Badan Pusat Statistik (BPS) yang diolah Kementerian Perindustrian, diketahui sepanjang tahun 2014 industri logam dasar besi dan baja tumbuh mencapai 6,93%. Pihak Perindustrian menilai sulit untuk mengukir pertumbuhan lebih tinggi dari realisasi tahun lalu.

Kementerian Perindustrian (KEMENPERIN) memproyeksikan bisnis pada semester II/2014 lebih bergeliat. Pasalnya iklim politik cenderung lebih stabil setelah pemilihan presiden dan wakilnya. Suasana politik yang sempat memanas jelang dan pasca pemilihan presiden (Pilpres) membuat para pebisnis menahan diri.

Pada tahun ini kementerian menargetkan pertumbuhan investasi mencapai 50% dari realisasi tahun lalu US$8 miliar. Jika persentase ini tercapai, artinya ada kapital baru yang tertanam di tanah air mencapai US$12 miliar. Mayoritas investasi baru mengalir ke industri besi dan baja, pengolahan nikel, bauksit serta industri pengolahan hilir. Untuk investor tembaga masih sulit, karena secara bisnis keuntungan yang didapat relatif kecil.

Minat investasi tidak hanya dipengaruhi stabilitas politik dan ekonomi domestik, tetapi juga ketersediaan energi misalnya listrik. Investor tidak hanya membutuhkan jaminan pasokan energi, melainkan pula harga yang sesuai keekonomian bisnis.

Industri baja diyakini terus tumbuh

Menurut Kementerian Perindustrian optimis sektor industri besi baja bakal terus tumbuh positif pada tahun ini, kendati masih ada sejumlah masalah yang berpotensi menjadi hambatan.

Menteri Perindustrian, Saleh Husin mengatakan, sedikitnya ada dua alasan besar atas keyakinan bertumbuh positifnya industri besi baja, yakni kinerja sektor tersebut dalam tiga tahun terakhir serta meningkatnya minat investasi.

Tahun 2014 lalu industri besi baja terus mengalami pertumbuhan positif, melihat cukup baiknya sektor besi baja dalam tiga tahun terakhir ini, menurut Menteri Perindustrian, Saleh Husin saat mengunjungi ke PT Krakatau Steel Tbk, Cilegon - Banten. Berdasarkan data Kementerian Perindustrian, pada sembilan bulan pertama tahun 2014 produksi baja tumbuh 10,74%.

Angka tersebut melebihi pertumbuhan rata-rata industri non migas yang hanya sebesar 5,30%. Pertumbuhan industri baja nasional ditopang oleh konsumsi baja dunia yang terus mengalami trend peningkatan sejak 2009 lalu. Bahkan trend pertumbuhan konsumsi baja secara global diprediksi terus meningkat hingga 2018. Namun pada periode 2011-2014 utilisasi kapasitas produk mengalami penurunan, karena pertumbuhan kapasitas melebihi pertumbuhan konsumsi.

Meskipun begitu, Saleh memprediksi, mulai tahun 2015 utilisasi kapasitas diperkirakan meningkat seiring dengan program pengurangan kapasitas di Cina. Sebagai perbandingan, pada periode Januari–September 2014 pertumbuhan industri non-migas nasional mengalami sedikit perlambatan yakni hanya 5,30%. Bandingkan dengan periode yang sama tahun lalu yang tumbuh 6,33%.

Perlambatan pertumbuhan industri non migas antara lain dipengaruhi oleh terus berlangsungnya ketidakpastian perekonomian dunia dan belum membaiknya kinerja neraca luar negeri nasional. Optimis terhadap pertumbuhan industri besi baja ini dikarenakan industri besi baja merupakan salah satu industri prioritas yang memegang peranan penting bagi pengembangan industri lainnya.

Contoh, selain sebagai bahan baku dasar industri seperti galangan kapal, migas, alat berat, automotif dan elektronika, industri besi baja merupakan pendukung utama pembangunan infrastruktur di Indonesia yang kini menjadi prioritas untuk meningkatkan daya saing industri dan penguatan struktur ekonomi nasional. Tetapi perlu disadari masih adanya banyak kendala riil yang dihadapi industri besi dan baja nasional.

Masalah utama yang dihadapi sektor tersebut adalah angka impor yang tinggi untuk bahan baku. Kendala lain yang dihadapi industri baja nasional adalah ketergantungan terhadap bahan baku dan komponen impor yang masih tinggi. Sedangkan, masalah internalnya adalah pemanfaatan pasar dalam negeri yang belum optimal.

Sementara menurut Direktur Utama PT Krakatau Steel Tbk, Irvan Kamal Hakim, masih ada beberapa kendala dan tantangan dari industri baja global, diantaranya adalah jatuhnya harga baja dunia. “Selama tiga tahun terakhir harga baja turun USD200 per ton menjadi sekitar USD500 per ton”.

Jatuhnya harga baja dunia disebabkan melemahnya kondisi ekonomi di Cina, sehingga berpengaruh pada industri baja di Indonesia. Dia mengilustrasikan, apabila terjadi penurunan Produk Domestik Bruto (PDB) sebesar 1% di Cina, maka akan ada kelebihan pasokan 24 juta ton baja di negeri tersebut.

“Dalam hal ini pelaku usaha dan pihak perindustrian telah melakukan langkah-langkah dan upaya, sehingga nanti ke depan industri baja diharapkan akan tumbuh dan berkembang di negeri sendiri, mengingat industri baja sebagai mother of industry”.

Konsumsi baja nasional (dominasi impor)

Kekurangan baja nasional (Juta ton)

DAFTAR ISI

BAB I PENDAHULUAN

1.1. Latar belakang

1.2. Tujuan dan ruang lingkup

1.3. Sumber data dan informasi

BAB II BAHAN BAKU, POTENSI DAN PELUANG

2.1. Klaster industri baja

2.2. Diagram input dan output

2.3. Potensi bijih besi di Indonesia

2.4. Endapan besi

2.5. Potensi bijih besi Indonesia

2.6. Tujuan konsep klaster industri baja

2.7. Peluang bijih besi dalam pemenuhan kebutuhan

komoditas mineral strategis nasional

2.7.1. Konsumsi dan produksi baja

2.7.2. Kondisi industri besi baja dalam negeri

2.7.3. Evaluasi

2.8. Statistik produksi bijih nikel, 2006-2014

2.9. Statistik produksi bauksit, 2006-2014

2.10. Statistik produksi bijih dan pasir besi, 2006-2014

2.11. Statistik produksi batu bara, 2004-2014

2.12. Statistik penjualan batu bara keluar negeri dan dalam negeri, 2004-2014

2.13. Statistik produksi batu bara, tahun 2004-2014

2.14. Perkembangan produksi barang tambang mineral

BAB III PROSES PEMBUATAN BESI DAN BAJA

3.1. Diagram pembuatan baja

3.1.1. Pembuatan besi kasar dan baja

3.2. Diagram pembuatan baja

3.3. Klasifikasi besi dan baja

3.4. Perlakuan panas pada besi dan baja

3.5. Dapur pengolah besi dan baja

3.5.1. Dapur tinggi

3.5.2. Dapur listrik

3.5.3. Dapur konvertor

3.5.4. Dapur siemen-martin

3.5.5. Dapur aduk

3.6. Jenis pipa untuk industri

3.6.1. Material Pipa

3.6.2. Proses pembuatan

3.6.3. Seamless Pipe

3.6.4. Butt-welded Pipe atau Straight welded pipe

3.6.5. Spiral Welded Pipe

3.7. Material penunjang dalam produksi baja

BAB IV TEKNOLOGI DAN EKONOMI

4.1. Penggunaan baja semakin dominan

4.2. Teknologi pembuatan besi dan baja

4.3. Aspek ekonomi pembuatan besi dan baja

4.4. Peranan sektor baja dalam perekonomian Indonesia

4.4.1. Sumber dan analisis data

4.4.2. Industri dan produk baja Indonesia di tahun sebelumnya

4.4.3. Kinerja industri dan konsumsi baja di tahun sebelumnya

4.4.4. Peran ekonomi industri baja

4.4.5. PDB dan konsumsi baja

BAB V PERANAN & PROSPEK INDUSTRI BAJA NASIONAL

5.1. Peranan

5.2. Pohon industri baja

5.3. Empat karakteristik utama industri baja

5.4. Kebutuhan baja nasional

5.5. Konsumsi baja per kapita

5.6. Proyeksi konsumsi baja 2020

5.7. Faktor-faktor yang mempengaruhi industri baja

5.8. Trend harga minyak

5.9. Trend harga iron core

5.10. Krisis industri baja global

5.11. Kondisi harga baja dunia (HRC, USD/ton)

5.12. Kinerja perusahaan baja dunia

5.13. Proyeksi pertumbuhan demand baja nasional, Tahun 2015-2020

5.14. Sumber daya mineral Indonesia terkait dengan industri baja

5.15. National Interest

5.16. Proyeksi pertumbuhan demand nasional baja utama dan baja turunan, 2015-2020

5.17. Keseimbangan kapasitas industri baja hulu dan hilir, Tahun 2014

BAB VI FGD PENYELARASAN ROADMAP INDUSTRI DAN PASAR BAJA NASIONAL

6.1. Dasar hukum

6.2. Roadmap industri baja

6.3. Nilai tambah mineral besi

6.4. Gambaran industri besi baja

6.5. Konsumsi baja per kapita vs GDP

6.6. Kebutuhan dan pasokan baja (crude steel)

6.7. Kebutuhan logam, mineral, dan listrik

6.8. Indikator kinerja utama industri besi baja

6.9. Perkembangan kapasitas industri besi baja

6.10. Proyeksi demand baja nasional

6.11. Proyeksi kapasitas dan supply baja nasional

6.12. Utilisasi kapasitas produk baja utama, 2013-2020

6.13. Permasalahan yang dihadapi dalam pengembangan industri logam berbasis mineral

6.14. Dukungan pemerintah yang diharapkan dalam pengembangan industri logam berbasis mineral

6.15. Produk baja kawat baja beton pratekan

6.15.1. PC strand (Produsen dan kapasitasnya)

6.15.2. PC wire (Produsen dan kapasitasnya)

6.15.3. PC bar (Produsen dan kapasitasnya)

6.16. Produk baja profil

6.16.1. Siku sama kaki (Produsen dan kapasitasnya)

6.16.2. H Beam (Produsen dan kapasitasnya)

6.16.3. I Beam (Produsen dan kapasitasnya)

6.16.4. WF (Produsen dan kapasitasnya)

6.16.5. Kanal U (Produsen dan kapasitasnya)

6.17. Produk baja long product

6.17.1. Baja tulangan beton (produsen &kapasitasnya)

6.17.2. Produsen BTB dan baja profil

6.17.3. Baja tulangan beton dalam bentuk gulungan

(Produsen dan kapasitasnya)

6.17.4. Aplikasi produk baja tulangan beton dan baja profil/beam

6.17.5. Produk baja flat product . Baja canai panas (BjP/HRC/HRP) – Produsen dan kapasitasnya

6.17.6. Produk baja flat product . Baja canai dingin (BjD/CRC/CRP) – Produsen dan kapasitasnya

6.17.7. Produk baja flat product . Pipa Spiral SAW (Submerged Arc Welding) dan Pipa ERW (Electric Resistance Welding) – Produsen dan kapasitasnya

BAB VII KONSERVASI ENERGI &PENGURANGAN EMISI CO2

7.1. Potret penggunaan dan intensitas energi

7.2. Kebutuhan teknologi

7.3. Peluang konservasi energi dan reduksi emisi

7.4. Analisis tingkat kelayakan investasi (invesment grade audit/IGA)

7.5. Sistem manajemen informasi energi dan emisi

7.6. Peningkatan kapasitas SDM industri

7.7. Roadmap program konservasi energi dan reduksi emisi di industri baja dan pulp-kertas

7.8. Kebijakan public

BAB VIII KONDISI PASAR

8.1. Seputar Krakatau Steel

8.1.1. Sejarah singkat

8.1.2. Mitra strategis lebih baik

8.1.3. Konsumsi naik

8.1.4. Mengoptimalkan Krakatau Steel

8.1.5. Empat syarat membeli Krakatau Steel (KS)

8.1.6. Dari bisnis baja sampai bisnis rumah sakit

8.1.7. Sepuluh anak perusahaan PT Krakatau Steel

8.1.8. Mitra strategis untuk meningkatkan produksi

8.1.9. Diharapkan produksi naik dua kali lipat

8.1.10. Profil para peminang PT Krakatau Steel

8.2. Merangsang perdagangan China-ASEAN

8.3. Kendala pasokan energi dan bahan baku perlu diantisipasi

8.4. Kebutuhan industri baja 13 juta ton tahun 2015

8.5. Investasi besi dan baja diproyeksi mencapai Rp382,6 Triliun

8.6. Tantangan industri baja nasional di tahun 2015

8.7. Prospek industri

8.7.1. Pengecoran logam

8.7.2. Bangun infrastruktur, Indonesia membutuhkan baja 17,46 juta ton

8.8. Industri baja rentan terhadap pelemahan harga minyak

8.9. Waktunya industri baja nasional terbebas dari bahan impor

8.10. Peluang investasi

8.11. Industri baja nasional butuh dukungan semua pihak

8.12. Baja Indonesia tidak lagi terkena Safeguard di Filipina

8.13. Proyek infrastruktur berkah bagi industri besi baja

8.14. Harga bijih besi turun

8.15. Pemerintah mendukung baja nasional menjadi industri strategis

8.16. Kekhawatiran dampak ekses Tiongkok terhadap industri baja nasional

8.18. Bangkitkan industri baja nasional

8.19. Dukungan penuh dari pemerintah terhadap industri baja nasional

8.20. Pemerintah terapkan anti-dumping

8.21. Steel Pipe Industry of Indonesia tercatat listing perdana 22 Februari 2013

8.22. Pipa baja produk PT Dwi Sumber Arca Waja berkelas dunia

8.23. Industri baja nasional akan tetap solid

8.24. Sektor konstruksi dongkrak pertumbuhan pipa baja 12%

8.25. Krakatau Steel mendapat pesanan perdana 2.700 pipa dari Pertamina

8.26. Industri baja tumbuh positif

8.27. Bakrie Pipe Industries akan akuisisi pabrik pipa baja baru

8.28. Bisnis Tenaris SA perkuat cengkeramannya di Indonesia

8.29. Ukuran pipa baja dan rumus menghitung beratnya

8.30. ISSP tambah kapasitas produksi pipa baja sebesar 100.000 ton per tahun

8.31. Tiga industri baja ekspansi US$ 1,8 miliar

8.32. Krakatau Steel garap energi, pipa, dermaga dan air bersih

8.33. Konsumsi baja Indonesia pada 2014 sebesar 8% menjadi 14,7 juta ton

8.34. Peta persebaran industri baja nasional

8.35. ISSP, saham pipa baja lokal yang layak dilirik

8.36. Bisnis PT Bakrie & Brothers, Tbk ke depan akan terfokus pada perkuatan bidang usaha berbasis manufaktur dan pengembangan infrastruktur

8.37. Industri baja nasional,peluang pangsa pasar yang besar

8.38. Statistik industri logam dasar, besi dan baja

8.39. Melihat kondisi industri baja nasional sebelumnya

8.39.1. Globalisasi perdagangan dunia

8.39.2. Aliansi strategis industri baja dunia

8.39.3. Posisi Indonesia

8.39.4. Potensi deposit bijih besi Indonesia

8.39.5. Permasalahan

8.39.6. Potensi pengembangan industri baja nasional

8.39.7. Retrukturisasi industri baja nasional

8.40. Produk hulu baja lembaran

8.40.1. Karakteristik produk

8.40.2. Produsen dan kapasitas produksi

8.40.3. Produsen utama

8.41. Pipa besi-baja

8.41.1. Industri perkapalan dan pipa menjadi favorit investasi

8.41.2. Pentingnya pipa dalam industri

8.41.3. Macam-macam pipa hollow

8.42. PT Steel Pipe Industri of Indonesia menargetkan pencapaian 8.000 ton/bulan

8.43. Ekspansi Growth Steel Group, PT. Krakatau Steel, dan Gunawan Steel Group senilai US$ 1,8 miliar

8.44. Menghadapi AEC 2015, industri besi-baja nasional perlu dorongan dari IISIA

8.45. Pabrik baja yang terbukti mencemari lingkungan, izinnya akan dicabut

8.46. Baja Indonesia berpeluang menguasai pasar ASEAN

8.47. Spindo memperbanyak pipa otomotif

8.48. Kinerja pabrik baja terbesar di Indonesia

8.49. Enam proyek strategis milik PT. Krakatau Steel diselesaikan tahun 2014

8.50. Lion membangun pabrik baja di Purwakarta

8.51. Pipa baja China merambah ke pasar Indonesia

8.52. Proyek migas dongkrak 20% utilisasi industri pipa baja nasional

8.53. Krakatau Steel miliki pabrik pipa baja dengan mesin dari China

8.54. PT Krakatau Steel di Bursa Efek Jakarta

8.55. ISSP target pendapatan 2015 mencapai Rp4,9 triliun

8.56. Harga anjlok, ekspor dan produksi bijih besi dibatasi

8.57. Ketentuan ekspor produk pertambangan

8.58. PT Saranacentral Bajatama catat kenaikan laba hingga 4.689%

8.59. Amerika Serikat menerapkan tarif 0% terhadap pipa

baja las karbonik eks Vietnam

8.60. Statistik perkembangan ekspor dan impor besi/baja

8.60.1. Nilai ekspor dan impor, 2009-2014

8.60.2. Volume ekspor dan impor, 2009-2014

8.60.3. Ekspor besi/baja berdasarkan negara tujuan

8.60.4. Impor besi/baja berdasarkan negara tujuan

8.61. Kondisi pasar baja global dan konsumsi baja nasional

8.61.1. Persaingan pasar baja global sangat ketat

8.61.2. Konsumsi baja nasional didominasi produk impor

8.61.3. Mekanisme impor besi/baja dan baja paduan

BAB IX PENGEMBANGAN INVESTASI INDUSTRI LOGAM DASAR

9.1. Pengelompokkan industri baja nasional

9.1.1. Industri hulu

9.1.2. Industri intermediate

9.1.3. Industri hillir

9.2. Alasan pengembangan industri baja

9.3. Karakteristik industri

9.3.1. Analisa pasar

9.3.1.1. Konsumsi baja dalam negeri

9.3.1.2. Produksi baja dalam negeri

9.3.1.3. Neraca perdagangan ekspor-impor

9.3.1.4. Kondisi pasar dunia

9.4. Bahan baku, sebaran dan proses produksi

9.4.1. Sebaran bahan baku

9.4.2. Proses produksi

9.5. Pelaku usaha di dalam negeri

9.5.1. Sebaran lokasi pelaku usaha

9.5.2. Kapasitas ijin, kapasitas terpasang & realisasi

9.5.3. Produk yang dihasilkan

9.6. Pelaku usaha diluar negeri

9.6.1. Sebaran produsen baja dunia

9.6.2. Produk yang dihasilkan

9.6.3. Teknologi proses produksi

9.6.4. Pengembangan kedepan

BAB X KEBIJAKAN SEKTOR INDUSTRI BAJA

10.1. Kebijakan di bidang penanaman modal

10.2. Kebijakan di bidang perdagangan

10.3. Kebijakan di bidang perpajakan

10.4. Kebijakan departemen teknis

BAB XI ARAH PENGEMBANGAN

11.1. Pengembangan komoditas

11.2. Pengembangan industri

11.3. Analisa SWOT

11.4. Lokasi pengembangan industri baja

11.4.1. Ketersediaan lahan

11.4.2. Ketersediaan sarana dan prasarana

11.4.3. Ketersediaan utilitas dalam kawasan

11.4.4. Ketersediaan supporting industries

11.4.5. Ketersediaan sumber daya manusia

11.4.6. Biaya doing business

11.5. Kendala pengembangan investasi

11.5.1. Permasalahan internal industri

11.5.2. Permasalahan eksternal

11.6. Hasil focus group discussion

BAB XII PERKEMBANGAN EKSPOR IMPOR

12.1. Pengertian ekspor dan impor

12.2. Kegiatan ekspor dan impor Indonesia

12.3. Manfaat kegiatan ekspor dan impor

12.4. Daftar pelabuhan di Indonesia

12.5. Impor pipa besi dan baja menurut negara asal utama

12.6. Nilai impor kendaraan bermotor menurut negara asal utama

12.7. Ekspor batu bara menurut negara tujuan utama

12.8. Ekspor minyak bumi mentah menurut negara tujuan utama

12.9. Nilai impor kendaraan bermotor menurut negara asal utama

12.10. Volume ekspor dan impor Migas

12.11. Impor minyak bumi dan hasil-hasilnya menurut negara asal utama

12.12. Ekspor gas menurut negara tujuan utama

12.13. Jumlah perusahaan konstruksi menurut provinsi

12.14. Ringkasan statistik konstruksi

12.15. Ringkasan pendapatan bruto dan pengeluaran perusahaan konstruksi

12.16. Nilai konstruksi yang diselesaikan menurut jenis pekerjaan

12.17. Nilai konstruksi yang diselesaikan menurut provinsi dan bidang pekerjaan

12.18. Daya terpasang, produksi, dan listrik terjual PT. PLN (Persero) menurut wilayah operasi

12.19. Daya terpasang PT PLN (Persero) menurut wilayah operasi PLN (MW)

12.20. Listrik yang didistribusikan kepada pelanggan menurut kelompok pelanggan

12.21. Kapasitas terpasang (MW) PLN menurut jenis pembangkit listrik

12.22. Produksi listrik PT. PLN (Persero) menurut wilayah operasi (ribu MWh)

12.23. Rincian ekspor besi dan baja, tahun 2011-2014

12.24. Rincian impor besi dan baja, Tahun 2010-2014

12.25. Rekap impor besi dan baja berdasarkan bulan, Tahun 2010-2014

12.26. Rekap ekspor besi dan baja berdasarkan bulan, Tahun 2010-2014

12.27. Perkembangan impor baja 5 tahun ke belakang, 2007-2011

12.28. Perkembangan ekspor baja 5 tahun ke belakang, 2007-2011

12.29. Perkembangan kinerja industri besar dan sedang (besi dan baja) berdasarkan KBL 5 tahun ke belakang, 2006-2010

BAB XIII INDUSTRI BAJA DIDUKUNG SEKTOR PENGGUNANYA

13.1. Konstruksi

13.1.1. Kebutuhan semen, baja dan aspal, 2013-2014

13.1.2. Supply – demand kebutuhan semen, baja dan aspal

13.1.3. Kebutuhan alat berat, 2013-2014

13.1.4. Supply – demand alat berat

13.1.5. Total ketersediaan alat berat nasional

13.1.6. Kebutuhan Baja Indonesia sebesar 80,4% disalurkan untuk sektor konstruksi & properti

13.1.7. Faktor-faktor dalam pemilihan alat berat konstruksi

13.2. Industri otomotif

13.2.1. Produk potongan baja pada kendaraan

13.2.2. Potensi market share industri pipa baja otomotif

13.2.3. Isu sentral

13.2.4. Pemasaran kendaraan dalam negeri dan perkembangan ekspor-impor menurut kategori (Januari-Mei) 2012-2015

13.2.5. Produksi kendaraan dalam negeri menurut kategori (Januari-Mei), 2015-2012

13.3. Sektor lainnya

BAB XIV PERANAN PERBANKAN

14.1. Peran perbankan

14.2. Aspek analisis pembiayaan kredit

14.2.1. Aspek hukum

14.2.2. Aspek manajemen

14.2.3. Aspek pemasaran

14.2.4. Aspek operasional dan teknis

14.2.5. Hubungan dengan bank

14.2.6. Risiko bisnis dalam sektor industri baja

14.2.7. Aspek keuangan

14.2.8. Struktur fasilitas kredit

14.2.9. Jenis pembiayaan dan jasa bank

14.3. Faktor penentu kesuksesan

14.4. Rekomendasi

BAB XV STANDAR NASIONAL INDONESIA

BAB XVI PERKUATAN STRUKTUR INDUSTRI NASIONAL

16.1. Kinerja sektor industri

16.1.1. Pertumbuhan ekonomi sampai dengan tahun 2014 (Triwulan I)

16.1.2. Pertumbuhan ekonomi dan sektor industri non migas Indonesia

16.1.3. Pertumbuhan industri pengolahan non migas menurut cabang-cabang industri

16.1.4. Nilai PDB sektoral dan kontribusinya terhadap PDB nasional

16.1.5. Kontribusi industri pengolahan non migas terhadap PDB nasional

16.1.6. Peran tiap cabang industri terhadap PDB sektor industri

16.1.7. Perkembangan ekspor industri non migas 2014

16.1.8. Perkembangan impor industri non migas, 2014

16.1.9. Perkembangan investasi PMDN sektor industri 2014 (Rp miliar)

16.1.10. Perkembangan investasi PMA sektor industri, 2014 (US$ Juta)

16.2. Pembangunan industri nasional (Undang-Undang No. 3 Tahun 2014 tentang Perindustrian)

16.2.1. Kebijakan pemanfaatan energi untuk sektor industri (Berdasarkan Undang-Undang No. 3 Tahun 2014)

16.2.2. Industri andalan

16.3. Konsumsi energi sektor industri

16.3.1. Konsumsi energi sektor industri tahun 2011 per provinsi

16.3.2. Konsumsi energi sub sektor industri 2006-2009

16.3.3. Komposisi penggunaan energi per sub sektor industri tahun 2009 – per jenis energi

16.3.4. Proyeksi kebutuhan energi (7 industri padat energi)

16.3.5. Kebutuhan energi pada program pengembangan kawasan industri

16.3.6. Proyeksi kebutuhan energi dalam rangka pengembangan kawasan industri periode 2012-2017

BAB XVII STATISTIK INDUSTRI BAJA NASIONAL

17.1. Total production of crude steel, 2004-213

17.2. Production of continuously-cast steel, 1992-2013

17.3. Production of crude steel in electric furnaces, 2004-2013

17.4. Production of hot rolled products, 2004-2013

17.5. Production of hot rolled long products, 2004-2013

17.6. Production of hot rolled flat products, 2004-2013

17.7. Production of hot rolled plate ( > 3mm ), 2004-2013

17.8. Production of hot rolled bars (other than concrete reinforcing bars), 2004-2013

17.9. Production of wire rod, 2004-2013

17.10. Production of tinmill products, 2004-2013

17.11. Production of other metal coated sheet and strip, 2004-2013

17.12. Production of non-metallic coated sheet and strip, 2004-2013

17.13. Total production of tubular products, 1994-2012

17.14. Production of welded tubes, 1994-2012

17.15. Exports of semi-finished and finished steel products, 1994-2012

17.16. Imports of semi-finished and finished steel products, 2004-2013

17.17. Exports of ingots and semis, 2004-2013

17.18. Imports of ingots and semis, 2004-2013

17.19. Exports and import of long products, 2004-2013

17.20. Exports and imports of flat products, 2004-2013

17.21. Exports and imports of tubular products, 2004-2013

17.22. Apparent steel use (crude steel equivalent) and Apparent steel use per capita (kg crude steel), 2004-2013

17.23. Apparent steel use (finished steel products) and Apparent steel use per capita (kg finished steel products), 2004-2013

17.24. Production of direct reduced iron, 2004-2013

17.25. Exports and imports of direct reduced iron, 2004-2013

17.26. Exports and imports of pig iron, 2004-2013

17.27. True steel use per capita (kg finished steel equivalent), 2003-2012

17.28. True steel use (finished steel equivalent), 2003-2012

17.29. Indirect net exports of steel, indirect imports of steel, and indirect exports of steel, 2003-2012

17.30. Imports and exports of scrap, 2004-2013

17.31. Imports and exports of iron ore, 2004-2013

17.32. Production of iron ore, 2004-2013

17.33. Imports and exports of pig iron, 2004-2013

17.34. Crude steel production (annual and monthly), 2005-2010

17.35. Crude steel production (annual and monthly), 2005-2010

17.36. Direct reduced iron production, 2004-2012

BAB XVIII PENUTUP

18.1 Kesimpulan

18.2. Permasalahan

18.3. Solusi

18.4. Rekomendasi

REGULASI

ENGLISH VERSION

Our customers love! Best wishes.

Hopefully we are all in God's protection!

Background Commercial Global Data Research (CDR)

Our customers love! Best wishes.

Hopefully we are all in God's protection!

We are an agency Consultant, Survey, Research and Reporting in the field of research data globally, serving a variety of actual business information covering the manufacturing industry sector, mining, banking, insurance, feasibility studies, and other research services.

We present as your consultant partner, to provide the actual information you need to determine the direction of policy in developing your company. One study book products that we offer to you is "BOOK STUDY ON THE MARKET CONDITIONS AND PROSPECTS OF STEEL INDUSTRY IN INDONESIA 2015".

We offer the book to you for Rp. 7,000,000 (Seven million rupiahs), to help businesses in the Steel Industry, to help the investors, helping the banks or creditors, and other related parties, by looking at the map of power among the competitors / partners, both foreign competition foreign and domestic, to study the development of the Export and Import of steel products in Indonesia, knowing the obstacles and opportunities for companies whose conditions fluctuate, knowing the Main Market of each company Baja, determine the share of overseas markets, as well as the other information you need to know.

How big is your company's contribution in increasing production capacity to fulfill orders from buyers both local and international, looking at every opportunity, and is expected to have this book, your company becomes more productive, efficient, more advanced and compete fairly.

P R E F A C E

The steel industry is one of the strategic industries in Indonesia. This sector plays a major role in supplying raw materials vital to development in various fields, ranging from the provision of infrastructure (buildings, roads, bridges, electricity and telecommunication networks), the production of capital goods (machinery plant and material support as well as spare parts), tool transport (ship, rail and rail, automotive), until weaponry. On a very important role, the existence of the steel industry to be very strategic for the prosperity of a country. Indonesia has a great potential to develop steel industry. The development is the development direction of investment. Therefore, the development of investment that can be performed on the steel industry were reviewed through market analysis that has been done, it is known still unmet demand in the country.

The need for the proposed development of the steel industry in the areas that have the potential for the development of the steel industry. In addition, the development of the upstream industry sectors needs to be done. The aim of this study is to enhance the development of the steel industry which play a strategic role for the nation, but it has not been done optimally to be a formidable industry in this country.

The development of the global steel consumption has sparked a growing steel industry to increase production capacity. As a result, the production of iron ore also increased significantly. It is estimated that a time will lead to scarcity and crisis of raw materials for the steel industry.

The results of the evaluation, needs iron ore for the steel industry PT. Krakatau Steel to operate for 20 years will experience a deficit of 283,980,127 tonnes. Thus it is reasonable iron ore into the national strategic mineral commodities run by the state.

For the long-term government policies are needed that support this national strategic interests.

Steel demand in 2015

Needs of ferrous metals in the domestic steel in 2015 is estimated to reach 13 million tons. While fulfilling the demand in 2014 and from the domestic industry has not been 100%.

According to the Director of Basic Materials Industry DG Base Metal Manufacturing Industry Ministry of Industry (Ministry of Industry), Budi Irmawan, that the trend of steel demand for the metal continues to rise.

In 2015, the need is influenced by the new cabinet policy towards acceleration of infrastructure projects. In 2014 then, the metal needs of the steel in the homeland as much as 12 million tons. Prognosis demand some 13 million tons in 2015 showed growth of around 8.3% against the target of 2014.

Yet all needs are met from domestic production, imports are about 40% of the requirement. The installed production capacity for domestic crude steel around 4 million tonnes. When it is processed into a product, then the amount to 8 million tons. Factory utilization is rather low at 60% to 70% because there are some specifications that can not be made domestically.

Throughout the first half of 2014, basic metal industries of iron and steel grew 1.42%. This percentage shrank drastically to the growth in the first half of last year reached 12.47%. This condition affected depreciation, increase in wages, soaring electricity tariffs, and presidential elections.

Based on data from the Central Statistics Agency (BPS), which processed the Ministry of Industry, known throughout the base metal industry in 2014 iron and steel grew to 6.93%. Industry parties assess hard to carve out a higher growth than last year.

The Ministry of Industry projected business in the second semester / 2014, more development. The reason is likely to be more stable political climate after the election of president and vice president. Was heated political atmosphere ahead of and after the elections (Election) makes the businessmen refrain.

This year the ministry is targeting investment growth reached 50% from last year's US $ 8 billion. If this percentage is reached, meaning that no new capital is embedded in the country reached US $ 12 billion. The majority of new investments flowed into the iron and steel industry, processing of nickel, bauxite and downstream processing industries. For investor copper is still difficult, because the business is relatively small benefits.

Investment interest not only influenced the domestic political and economic stability, but also the availability of energy such as electricity. Investors not only need energy security, but also the price of the corresponding business economics.

The steel industry is believed to continue to grow

According to the Ministry of Industry optimistic sector, the steel industry will continue to grow positively this year, although there are still a number of issues that could potentially become a bottleneck.

Minister of Industry, Saleh Husin said, there are at least two major reasons on growing confidence plus the steel industry, namely the performance of the sector in the last three years and increased investment interest.

In 2014 the steel industry continues to experience positive growth, look pretty good iron and steel sector in the last three years, according to the Minister of Industry, Saleh Husin while visiting Tbk to PT Krakatau Steel, Cilegon - Banten. Based on data from the Ministry of Industry, in the first nine months of 2014 steel production grew 10.74%.

The figure exceeded the average growth in non-oil industry which only amounted to 5.30%. The growth of the national steel industry is supported by the world steel consumption continues to experience an increasing trend since 2009. Even the trend of global steel consumption growth is predicted to continue to increase until 2018. However, in the period from 2011 to 2014 capacity utilization decreased product, because growth capacity exceeds consumption growth.

Even so, Saleh predicts, started in 2015 capacity utilization is expected to increase in line with the capacity reduction program in China. For comparison, in January-September 2014 the growth of non-national oil and gas industry experienced a slight slowdown which is only 5.30%. Comparing with the same period last year grew 6.33%.

Slowing the growth of non-oil industries, among others, influenced by the continuing global uncertainty and lack of improvement in external balance of national performance. Optimistic on the growth of the steel industry is because the steel industry is one of the priority industries play an important role for the development of other industries.

Examples, other than as a basic raw material industries such as shipbuilding, oil and gas, heavy equipment, automotive and electronics, iron and steel industry is a major supporter of infrastructure development in Indonesia, which is now a priority to improve industrial competitiveness and strengthening the structure of the national economy. But be aware there is still a lot of real constraints facing national iron and steel industry.

The main problem facing the sector is the high import figures for raw materials. Another obstacle faced by the national steel industry is the dependence on imported raw materials and components is still high. Meanwhile, the internal problem is the utilization of the domestic market is not optimal.

Meanwhile, according to Director of PT Krakatau Steel Tbk, Irvan Kamal Hakim, there are still some obstacles and challenges of the global steel industry, including the collapse of the world steel prices. "Over the last three years, steel prices fell US $ 200 per ton to about US $ 500 per ton".

The fall of world steel prices due to weakening economic conditions in China, so the effect on the steel industry in Indonesia. He illustrates, when a decline in the Gross Domestic Product (GDP) by 1% in China, then there will be an excess supply of 24 million tonnes of steel in the country.

"In this case the business and the industry has made steps and efforts, so that later forward the steel industry is expected to grow and develop in their own country, given the steel industry as the mother of industry".

National steel consumption (dominance of imports)

Steel consumption per capita

LIST OF CONTENTS

CHAPTER I INTRODUCTION

1.1. Background

1.2. Objectives and scope

1.3. Sources of data and information

CHAPTER II RAW MATERIALS, POTENTIAL AND OPPORTUNITIES

2.1. Cluster steel industry

2.2. Diagram of input and output

2.3. Potential iron ore in Indonesia

2.4. Precipitation of iron

2.5. Potential iron ore Indonesia

2.6. Purpose steel industry cluster concept

2.7. Iron ore opportunities in fulfillment national strategic mineral commodities

2.7.1. Consumption and production of steel

2.7.2. The condition of the domestic steel industry

2.7.3. Evaluation

2.8. Nickel ore production statistics, 2006-2014

2.9. Bauxite production statistics, 2006-2014

2.10. Statistics of production of iron ore and sand, 2006-2014

2.11. Coal production statistics, 2004-2014

2.12. Statistics coal sales abroad and within the country, 2004-2014

2.13. Coal production statistics, in 2004-2014

2.14. Development of mineral production of mining products

CHAPTER III PROCESS OF IRON AND STEEL

3.1. Diagram steelmaking

3.1.1. Manufacture of pig iron and steel

3.2. Diagram steelmaking

3.3. Classifications iron and steel

3.4. Heat treatment on iron and steel

3.5. Processing of iron and steel kitchen

3.5.1. High kitchen

3.5.2. Electric kitchen

3.5.3. Kitchen converter

3.5.4. Kitchen siemen-martin

3.5.5. Kitchen stirring

3.6. Types of pipes for industry

3.6.1. Material Pipe

3.6.2. Making process

3.6.3. Seamless Pipe

3.6.4. Butt-welded Pipe or Straight welded pipe

3.6.5. Spiral Welded Pipe

3.7. Supporting material in steel production

CHAPTER IV TECHNOLOGY AND ECONOMY

4.1. The use of increasingly dominant steel

4.2. Iron and steel-making technology

4.3. Economic aspects of the manufacture of iron and steel

4.4. The role of the steel sector in the economy of Indonesia

4.4.1. Sources and data analysis

4.4.2. Indonesian industrial and steel products in the previous year

4.4.3. Industry performance and consumption of steel in the previous year

4.4.4. The economic role of the steel industry

4.4.5. GDP and steel consumption

CHAPTER V THE ROLE & OUTLOOK NATIONAL STEEL INDUSTRY

5.1. Role

5.2. Trees steel industry

5.3. The four main characteristics of the steel industry

5.4. National steel demand

5.5. Steel consumption per capita

5.6. Projections steel consumption in 2020

5.7. Factors affecting the steel industry

5.8. Oil price trend

5.9. Price trend iron core

5.10. Global steel industry crisis

5.11. The condition of the world steel prices (HRC, USD / ton)

5.12. Steel company's performance

5.13. National steel demand growth projections, Year 2015-2020

5.14. Indonesian mineral resources associated with the steel industry

5.15. National Interest

5.16. Projected growth in national demand of major steel and steel derivative, 2015-2020

5.17. The balance of the capacity of upstream and downstream steel industry, 2014

CHAPTER VI FGD ROADMAP ALIGNMENT OF NATIONAL STEEL INDUSTRY AND MARKET

6.1. Legal basis

6.2. Roadmap steel industry

6.3. The added value of iron minerals

6.4. Overview of the steel industry

6.5. Steel consumption per capita vs. GDP

6.6. Demand and supply of steel (crude steel)

6.7. Needs metals, minerals, and electricity

6.8. Key performance indicators of the steel industry

6.9. The development of the capacity of the steel industry

6.10. National steel demand projections

6.11. Projection and supply of national steel capacity

6.12. Capacity utilization major steel products, 2013-2020

6.13. Problems faced in the development of mineral-based metal industry

6.14. Government support is expected in the development of mineral-based metal industry

6.15. Steel products of prestressed concrete steel wire

6.15.1. PC strand (Manufacturer and capacity)

6.15.2. PC wire (Manufacturer and capacity)

6.15.3. PC bar (Manufacturer and capacity)

6.16. Profile steel products

6.16.1. Isosceles (Manufacturer and capacity)

6.16.2. H Beam (Manufacturer and capacity)

6.16.3. I Beam (Manufacturer and capacity)

6.16.4. WF (Manufacturers and capacity)

6.16.5. Channel U (Manufacturers and capacity)

6.17. Product of long steel products

6.17.1. Concrete reinforcing steel (manufacturers & capacity)

6.17.2. BTB and steel manufacturer profiles

6.17.3. Concrete reinforcing steel in coils

(Manufacturers and capacity)

6.17.4. Application of concrete reinforcing steel products and steel profiles / beam

6.17.5. Flat product steel products. hot rolled steel (BJP / HRC / HRP) - Manufacturer and capacity

6.17.6. Product flat steel products. Cold rolled steel (BJD / CRC / CRP) - Manufacturer and capacity

6.17.7. Product flat steel products. Pipe Spiral SAW (Submerged Arc Welding) and Pipe ERW (Electric Resistance Welding) - Manufacturer and capacity

CHAPTER VII ENERGY CONSERVATION & CO2 EMISSION REDUCTION

7.1. Images of use and energy intensity

7.2. Technological needs

7.3. Opportunity of energy conservation and emission reduction

7.4. Analysis of the feasibility of investment (investment grade audit / IGA)

7.5. Energy information management systems and emissions

7.6. Capacity building industry

7.7. Roadmap program of energy conservation and emission reduction in the steel industry and pulp-paper

7.8. Public policy

CHAPTER VIII MARKET CONDITIONS

8.1. Regarding Krakatau Steel

8.1.1. A brief History

8.1.2. Better strategic partner

8.1.3. Consumption rose

8.1.4. Optimizing Krakatau Steel

8.1.5. Four conditions buying Krakatau Steel (KS)

8.1.6. From the steel business to business hospital

8.1.7. Ten subsidiary PT Krakatau Steel

8.1.8. Strategic partners to increase production

8.1.9. Production is expected to double

1.8.10. Profiles of the suitor PT Krakatau Steel

8.2. China-ASEAN trade stimulates

8.3. Energy supply constraints and raw materials should be anticipated

8.4. The steel industry needs 13 million tons in 2015

8.5. Iron and steel investment is projected to reach Rp382.6 Trillion

8.6. The challenges of the national steel industry in 2015

8.7. Industry prospects

8.7.1. Foundry

8.7.2. Building infrastructure, Indonesia requires steel 17.46 million tons

8.8. The steel industry is vulnerable to weakening oil prices

8.9. Time national steel industry is free from material import

8.10. Investment opportunities

8.11. The national steel industry need the support of all parties

8.12. Steel Indonesia is no longer exposed to Safeguard in Philippines

8.13. Infrastructure projects godsend for steel industry

8.14. Iron ore prices down

8.15. The Government supports the national steel into strategic industries

8.16. China's concern about the excesses of the national steel industry

8.17. The steel industry needs to invest US $ 14 billion

8.18. Awaken the national steel industry

8.19. Full support of the government against the national steel industry

8.20. The government has applied anti-dumping

8.21. Steel Pipe Industry of Indonesia recorded listing premiere February 22, 2013

8.22. Steel pipe products PT Dwi Sumber Arca Waja world class

8.23. The national steel industry will remain solid

8.24. Jack construction sector growth of steel pipes 12%

8.25. Krakatau Steel received an order for 2,700 prime pipe from Pertamina

8.26. Positive growth in the steel industry

8.27. Bakrie Pipe Industries will be the acquisition of a new steel pipe plant

8.28. Business Tenaris SA strengthens its hold in Indonesia

8.29. Size steel pipe and calculate the formula weighing

8.30. ISSP-added steel pipe production capacity of 100,000 tons per year

8.31. Three steel industry US $ 1.8 billion expansion

8.32. Krakatau Steel working on energy, pipelines, docks and water

8.33. Indonesian steel consumption in 2014 by 8% to 14.7 million tons

8.34. Map of the distribution of the national steel industry

8.35. ISSP, shares decent local steel pipe glance

8.36. Business PT Bakrie & Brothers Tbk future will be focused on strengthening the business field based manufacturing and infrastructure development

8.37. The national steel industry, a large market share opportunities

8.38. Statistics basic metal industry, iron and steel

8.39. Seeing the condition of the national steel industry earlier

8.39.1. Globalization of world trade

8.39.2. The world steel industry strategic alliance

8.39.3. Position Indonesia

8.39.4. Potential deposits of iron ore Indonesia

8.39.5. Issues

8.39.6. The potential development of the national steel industry

8.39.7. Restructuring the national steel industry

8.40. Upstream steel sheet products

8.40.1. Product characteristics

8.40.2. Producers and production capacity

8.40.3. The main producers

8.41. Iron-steel pipe

8.41.1. Shipbuilding industry and become a favorite investment pipeline

8.41.2. The importance of pipelines in the industry

8.41.3. Various hollow pipe

8.42. PT Steel Pipe Industry of Indonesia is targeting 8,000 tonnes / month

8.43. Expansion Growth Steel Group, PT. Krakatau Steel, and Gunawan Steel Group worth US $ 1.8 billion

8.44. Facing the AEC in 2015, the iron-steel industry nationwide need encouragement from IISIA

8.45. Steel mills which proved to pollute the environment, its license will be revoked

8.46. Indonesian steel market likely to dominate ASEAN

8.47. Spindo reproduce automotive pipe

8.48. The performance of the largest steel mill in Indonesia

8.49. Six strategic project owned by PT. Krakatau Steel completed in 2014

8.50. Lion build steel plant in Purwakarta

8.51. Chinese steel pipe penetrated the Indonesian market

8.52. Oil and gas projects jack 20% utilization of domestic steel pipe industry

8.53. Krakatau Steel have steel pipe plant with machines from China

8.54. PT Krakatau Steel in the Jakarta Stock Exchange

8.55. ISSP targets 2015 revenue reached 4.9 trillion

8.56. Prices plummeted, export and production of iron ore is limited

8.57. Provisions mining product exports

8.58. PT Saranacentral Bajatama record profit increase of up to 4,689%

8.59. United States imposed tariffs of 0% to the pipe

welding steel carbonic former Vietnam

8.60. Statistics export and import growth of iron / steel

8.60.1. The value of exports and imports, 2009-2014

8.60.2. The volume of exports and imports, 2009-2014

8.60.3. Exports of iron / steel by country of destination

8.60.4. Imports of iron / steel by country of destination

8.61. Global steel market conditions and national steel consumption

8.61.1. Competition is very tight global steel market

8.61.2. Dominated national steel consumption of imported products

8.61.3. Import mechanism of iron / steel and alloy steel

CHAPTER IX DEVELOPMENT INVESTMENT INDUSTRY BASE METAL

9.1. Grouping the national steel industry

9.1.1. The upstream industry

9.1.2. Industrial intermediate

9.1.3. Downstream industries

9.2. The reason the development of the steel industry

9.3. Characteristics of the industry

9.3.1. Market analysis

9.3.1.1. Domestic steel consumption

9.3.1.2. Domestic steel production

9.3.1.3. Import-export trade balance

9.3.1.4. World market conditions

9.4. Raw materials, distribution and production processes

9.4.1. Distribution of raw materials

9.4.2. Production process

9.5. Perpetrators of domestic business

9.5.1. Distribution location businesses

9.5.2. License capacity, the installed capacity and the realization

9.5.3. The resulting product

9.6. Business operators overseas

9.6.1. Distribution of world steel producers

9.6.2. The resulting product

9.6.3. Production process technology

9.6.4. Future development

CHAPTER X POLICY STEEL INDUSTRY SECTOR

10.1. Policy in the field of investment

10.2. Policy in the field of trade

10.3. Policy in the field of taxation

10.4. Policies technical department

CHAPTER XI DEVELOPMENT DIRECTION

11.1. Commodity development

11.2. Industrial development

11.3. SWOT Analysis

11.4. Location development of the steel industry

11.4.1. Availability of land

11.4.2. The availability of facilities and infrastructure

11.4.3. Availability of utilities in the area

11.4.4. Availability supporting industries

11.4.5. The availability of human resources

11.4.6. The cost of doing business

11.5. Constraints investment development

11.5.1. Internal problems of the industry

11.5.2. External issues

11.6. The results of focus group discussion

CHAPTER XII IMPORT EXPORT DEVELOPMENT

12.1. Understanding export and import

12.2. Indonesia export and import activities

12.3. The benefits of export and import activities

12.4. List of ports in Indonesia

12.5. Iron and steel pipe imports by country of origin main

12.6. The value of imports of motor vehicles by the main countries of origin

12.7. Coal exports by main destination countries

12.8. Crude petroleum exports by main destination countries

12.9. The value of imports of motor vehicles by the main countries of origin

12.10. The volume of exports and imports of oil and gas

12.11. Imports of petroleum and its results according to the main country of origin

12.12. Gas exports by main destination countries

12.13. The number of construction companies by province

12.14. Summary statistics construction

12.15. Summary of gross revenues and expenses of construction companies

12.16. Value of construction completed by type of work

12.17. Value of construction completed by province and field work

12.18. Installed power, production, and electricity sold to PT. PLN (Persero) by operating region

12.19. Power installed PT PLN (Persero) according to the operating area PLN (MW)

12.20. The electricity is distributed to the customer by customer groups

12.21. Installed capacity (MW) PLN by type of power plant

12.22. Electricity production PT. PLN (Persero) according to the operating area (thousand MWh)

12.23. Details of exports of iron and steel, in 2011-2014

12.24. Details of iron and steel imports, in 2010-2014

12.25. Recap imports of iron and steel by month, year 2010-2014

12.26. Recap export of iron and steel by month, year 2010-2014

12.27. Development of steel imports last 5 years, 2007-2011

12.28. The development of steel exports last 5 years, 2007-2011

12.29. The development of the performance of large and medium industries (iron and steel) based KBL last 5 years, 2006-2010

CHAPTER XIII STEEL INDUSTRY SECTOR SUPPORTED USERS

13.1. Construction

13.1.1. Demand for cement, steel and asphalt, 2013-2014

13.1.2. Supply - demand demand for cement, steel and bitumen

13.1.3. Demand for heavy equipment, 2013-2014

13.1.4. Supply - demand heavy equipment

13.1.5. The total availability of the national heavy equipment

13.1.6. Steel Indonesia needs by 80.4% disbursed for the construction and property sector

13.1.7. The factors in the selection of heavy construction equipment

13.2. Automotive industry

13.2.1. Pieces of steel products in vehicles

13.2.2. Potential market share of automotive steel pipe industry

13.2.3. The central issue

13.2.4. Marketing of vehicles in the country and the development of export-import according to category (January-May) 2012-2015

13.2.5. Domestic vehicle production by category (January-May), 2015-2012

13.3. Others sector

CHAPTER XIV THE ROLE OF BANKING

14.1. The role of banks

14.2. Aspect analysis of credit financing

14.2.1. Legal aspects

14.2.2. Aspects of management

14.2.3. Marketing aspects

14.2.4. Operational and technical aspects

14.2.5. Relations with bank

14.2.6. Business risks in the steel industry sector

14.2.7. Financial aspect

14.2.8. The structure of the credit facility

14.2.9. Types of financing and banking services

14.3. Determinants of success

14.4. Recommendation

CHAPTER XV INDONESIAN NATIONAL STANDARD

CHAPTER XVI INDUSTRY STRUCTURE STRENGTHENING OF NATIONAL

16.1. Industry sector performance

16.1.1. Economic growth until 2014 (First Quarter)

16.1.2. Economic growth and non-oil industrial sector Indonesia

16.1.3. The growth of non-oil processing industry according to industry branches

16.1.4. The value of sectoral GDP and its contribution to national GDP

16.1.5. The contribution of non-oil and gas industries to the national GDP

16.1.6. The role of each branch of industry to GDP industrial sector

16.1.7. The development of non-oil industrial exports in 2014

16.1.8. The development of non-oil import industry, 2014

16.1.9. The development of domestic investment industry sector in 2014 (USD billion)

16.1.10. The development of foreign investment industrial sector, 2014 (US $ Million)

16.2. National industrial development (Act No. 3 of 2014 concerning Industry)

16.2.1. Energy utilization policy for the industrial sector (Based on Law No. 3 2014)

16.2.2. Industry mainstay

16.3. Energy consumption of the industrial sector

16.3.1. Industrial sector energy consumption in 2011 per province

16.3.2. The energy consumption of industrial sub-sectors 2006-2009

16.3.3. The composition of energy use per sub-sector in 2009 - per type of energy

16.3.4. Projections of energy requirements (energy-intensive industries 7)

16.3.5. Energy requirements in an industrial area development program

16.3.6. Projections of energy needs in the context of the development of industrial zones 2012-2017 period

CHAPTER XVII STATISTIC OF STEEL IN INDONESIA

17.1. Total production of crude steel, 2004-213

17.2. Production of continuously-cast steel, 1992-2013

17.3. Production of crude steel in electric furnaces, 2004-2013

17.4. Production of hot rolled products, 2004-2013

17.5. Production of hot rolled long products, 2004-2013

17.6. Production of hot rolled flat products, 2004-2013

17.7. Production of hot rolled plate ( > 3mm ), 2004-2013

17.8. Production of hot rolled bars (other than concrete reinforcing bars), 2004-2013

17.9. Production of wire rod, 2004-2013

17.10. Production of tinmill products, 2004-2013

17.11. Production of other metal coated sheet and strip, 2004-2013

17.12. Production of non-metallic coated sheet and strip, 2004-2013

17.13. Total production of tubular products, 1994-2012

17.14. Production of welded tubes, 1994-2012

17.15. Exports of semi-finished and finished steel products, 1994-2012

17.16. Imports of semi-finished and finished steel products, 2004-2013

17.17. Exports of ingots and semis, 2004-2013

17.18. Imports of ingots and semis, 2004-2013

17.19. Exports and import of long products, 2004-2013

17.20. Exports and imports of flat products, 2004-2013

17.21. Exports and imports of tubular products, 2004-2013

17.22. Apparent steel use (crude steel equivalent) and Apparent steel use per capita (kg crude steel), 2004-2013

17.23. Apparent steel use (finished steel products) and Apparent steel use per capita (kg finished steel products), 2004-2013

17.24. Production of direct reduced iron, 2004-2013

17.25. Exports and imports of direct reduced iron, 2004-2013

17.26. Exports and imports of pig iron, 2004-2013

17.27. True steel use per capita (kg finished steel equivalent), 2003-2012

17.28. True steel use (finished steel equivalent), 2003-2012

17.29. Indirect net exports of steel, indirect imports of steel, and indirect exports of steel, 2003-2012

17.30. Imports and exports of scrap, 2004-2013

17.31. Imports and exports of iron ore, 2004-2013

17.32. Production of iron ore, 2004-2013

17.33. Imports and exports of pig iron, 2004-2013

17.34. Crude steel production (annual and monthly), 2005-2010

17.35. Crude steel production (annual and monthly), 2005-2010

17.36. Direct reduced iron production, 2004-2012

CHAPTER XVIII CLOSING

18.1 Conclusion

18.2. Issues

18.3. Solutions

18.4. Recommendation

REGULATIONS

COMPANY PROFILES

Equipped with : COMPANY PROFILES STEEL PRODUCER IN INDONESIA

ASIAN PROFILE INDOSTEEL, PT

A d d r e s s : Office & Factory

Jl. Margomulyo Permai 32 Kav. 9

Surabaya 60183, East Java, Indonesia

Phones : +62 (031) 7481064

Fax. : +62 (031) 7496135

e-mail : api@api.co.id

Website : http://www.api.co.id/

Date of Establishment : March 12th, 1999

Total Investment : Initial

a. Equity Capital – Rp. 38,000 million

b. Loan Capital – Rp. 40,800 million

c. Total Investment – Rp. 78,800 million

Expansion

Total Investment – Rp. 45,000 million

Capitalization : a. Authorized Capital - Rp. 38,000,000,000

b. Issued Capital - Rp. 38,000,000,000

c. Paid Up Capital - Rp. 38,000,000,000

Legal Status : PT (Limited Liability Company)

Category : National Private and Domestic Investment

(PMDN) Company

Condition of Company : G o o d

Lines of Business : Steel Building Materials Manufacturing

Products/Services : SNI plain concrete iron, SNI threaded

concrete steel, Iron virkan / Nako

Type of Products : Manufacturers

Production Capacity : Initial

- Concrete Steel (Smooth) – 48,000 tons p.a.

- Concrete Steel (Screw) – 48,000 tons p.a.

Expansion

- Billet – 20,000 mt p.a.

P e r m i t s : The Capital Investment Coordinating Board

- No. 33/I/PMDN/1999 Dated 4 June 1999

- No. 111/II/PMDN/2007 Dated 21 August 2007

The Department of Industry

No. 345/T/INDUSTRI/2000 Dated 09 June 2000

Total Employees : 100 persons

Main Shareholders / : - Mr. Lucas, SH.

Parent company - Mr. Go Mulyadi utomo

- Mr. Sukianto Widjaja

B a n k e r s : - PT Bank CENTRAL ASIA Tbk.

- PT Bank MANDIRI Tbk.

Main Markets : Domestic & Export

Started Operation : 2001

Certificates/Awards : 2002 - Certificate of fire brand

2005 - Certificate of SNI plain concrete iron

2008 - Award best investment company

2010 - ISO 9001: 2008

2012 - The best quality product & service excellent of the year

Supervisory Board : Mr. Sukianto Widjaja (Member)

Board of Management : Mr. Yusuf Slamet (Director)

Associated Companies : - PT BHIRAWA STEEL

- PT GUNUNG BAJA

- UD NAGA JAYA

- CV TIGA BHAKTI

- PT WIJAYA MITRA MEGA PERKASA

R E M A R K S :

PT. Asian Profile Indosteel (PT. API) was founded in 1999 and its presence in the steel industry has been a consistent and recognized by the national market. PT. API goal is to become the benchmark of the steel industry in Indonesia, through the achievement of perfection of the quality of labor, product innovation and overall company performance. To support this goal, applying PT. API culture committed to the achievement of the targets, the discipline of the safety and social responsibility, continuous improvisation, openness and transparency.

FORMULIR PEMESANAN

ORDER FORM

Kirimkan kepada kami buku : “STUDI TENTANG KONDISI PASAR DAN PROSPEK INDUSTRI BAJA DI INDONESIA 2015”

Send us the book : "STUDY ON THE MARKET CONDITIONS AND PROSPECTS OF STEEL INDUSTRY IN INDONESIA 2015”.

Silahkan pilih versi buku anda

Please select the version of your book

Versi/version : √ ( ) Indonesia atau/or ( ) English

Tanggal Pemesanan : ……………………………………………………………

Booking date

Nama Pemesan : ……………………………………………………………

Name of buyer

Jabatan : ………………………………………………………

Position

Nama Perusahaan : ………………………………………………………

Name of Company

Alamat Perusahaan : ……………………………………………………

Company Address

Telepon/Fax : ……………………………………………………

Phone/Fax

Email : …………………………………………………

Hubungi kami / Contact Us :

DENI SILALAHI (Marketing Department) “Commercial Global Data Research”

Address : Sukamanah RT. 04/06 No. 199 Cisaat, Sukabumi, West Java – INDONESIA

Phone : +62 085793929829; +62 (0266) 9296038; E-mail. cg.dataresearch@gmail.com

Pembayaran melalui : √ Cash Cheque Transfer

Payment via

Nama Bank : BANK OCBC NISP

Bank name Cabang Sukabumi

Nomor Rekening : 14081015480-1

Account number

Rekening atas nama : ROHIYAH

Account in the name

Buku pesanan Anda akan segera kami kirim setelah ada konfirmasi dari pihak pemesan.

Book your order will immediately tell us when there is confirmation from the buyer

Terima kasih atas kepercayaan anda bermitra dengan kami.

Thank you for the trust you partner with us.

Hormat kami / sincerely

Pemesan / Buyer,

____________________________